- Home

-

Production Lines Options

- Candy Production Line

- Gingerbread Production Line

- Cookies Production Line

- Eclairs, Profiteroles, Cupcakes Production Line

- Marshmallow Production Line

- Cookie Sandwiches Production Line

- Halva, Nougat, Iris, Bars Production Line

- Cakes Production Line

- Wafer Sugar Cone with Marshmallows Production Line

- Сurd Snacks Production Line

- Semi-finished Products Production Line

-

Neofood Modules

- IntelleDrop - Multi Lane Food Piston Depositor

- IntelleMix - Molding Machine for Combined Confectionery and Gastronomic Products

- IntelleStamp - Confectionery Auger Extruder

- IntelleGlaze - Enrobing and Decorating Machine

- IntelleWaferBall - Wafer Ball Production Line

- IntelleWaferRoll - Wafer Rolls, Sticks And Bars Production Line

- Intelletartlet - Dispensing Liquid Masses Into Tartlets

- IntelleCone - Waffle Cone Filling Line

- IntelleCake - Fillings Injection Module

- Intellemixer - Mixing And Aerating (Whipping) Machine

- Intelleoven - Confectionery Tunnel Oven

- IntelleCool - Continuous Combined Cooling Tunnel

- IntelleDrive - Central Operations Control Panel

- IntelleRobotics - Robotic Finishing System

- Vending Machines

- Info

- Contact Us

Site last updated: April 12, 2024

IntelleStamp - Two-component Auger-type Molding and Extrusion Machine for Molding Products from Masses of Solid Viscosity

IntelleStamp is a modern two-component auger-type molding and extrusion complex for molding products from masses of a solid viscosity level (iris, nougat, hematogen, gingerbread custard, soft roasting, chilled dense curd mass) with fillings of a liquid viscosity level. It allows extruding masses with the addition of particles of 3-5 mm (walnut, raisins, candied fruits, etc.).

IntelleStamp is equipped with:

- powerful auger extrusion system;

- three modern cutting systems - diaphragm, string and guillotine;

- filling module.

Only our equipment allows to produce a calibrated product, equal in weight and shape (due to the use of individual dispensers in the heads of each type), which will allow you to produce a product packaged in boxes, cells and packaging, suitable for promotion in any market and in any trading network!

It is possible to use a machine with rotary kilns (while maintaining the possibility of an upgrade to work with a tunnel kiln).

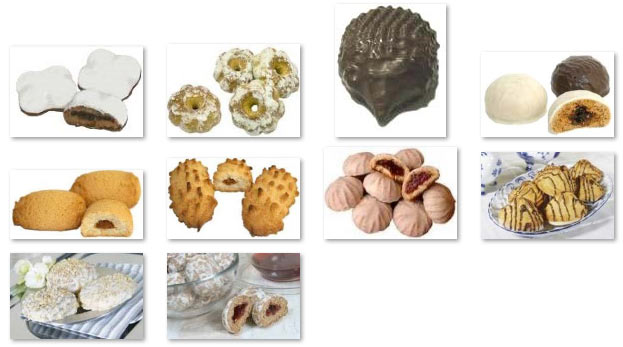

A few product examples:

The universal Neofood module for semi-automatic and automatic production methods, can easily be combined with other modules to obtain even more complex combined products. Possible delivery of a kit for self-assembly. Provided with detailed video instructions for assembly and commissioning.

Attention! Our equipment lines are formed individually for the client. Any example presented on the site may be:

A) expanded to produce a wider range of products,

B) expanded for greater performance,

C) cheaper for maximum availability, with the possibility of subsequent "upgrade" to the older model.

Contact us for more details!

Key Features:

1) High productivity - up to 700 kg / h.

2) The mechanism of diaphragm cutting of products is a high-speed method of forming products with filling. Products are “rolled” with cams, the filling does not protrude beyond the edges.

3) The mass distribution system in the auger chamber consists of six or more screws (depending on the number of jets) and a cutting roller.

4) High accuracy of dosing, distribution of product rows and speed of the machine is achieved thanks to the smooth adjustment of each of the drives operating from frequency converters.

5) Production of round, flat and oblong products.

6) Easy-change nozzles of various modifications and purposes.

7) Easily replaceable knots of molding, string cutting.

8) The ability to install additional modules, such as: press roller, sub-stamping unit, etc.

9) A detailed menu of machine settings with the program bank.

10) Electronic event log - allows you to fully control the operation of the machine.

11) The ability to simultaneously manufacture products with different fillings (assorted).

12) A large selection of nozzles, individual production.

13) Modification of the complex with installation on a tunnel kiln.

Specifications:

Length: 900 mm;

Working width: 1000, 800, 600,300 mm;

Height: 700 mm;

Power: 2.8 kW;

Electrical connection: 3-phase, 380 ± 5 V, frequency 50 Hz;

Maintenance: temperature + 15 ° C - + 35 ° C, humidity not more than 65%;

Necessary atmospheric pressure: 7-8 atm;

Air volume for pneumatic systems: 550 l / min;

Productivity: 1200 cycles / hour;

Dough hopper volume: 35 L;

The filling hopper volume is 60 l;

Diaphragm, string and guillotine cutting;

Maximum temperature: 70 ° C;

Pneumatic system: Festo in the cutting system;

Material: Stainless steel (AISI304), 1.5 mm thickness. Steel parts, aluminum and cestiline (recommended in the food industry). Thickness of internal parts - on request;

Sensors: Siemens for the functioning of the head and for the mass level;

Motor gearbox: Sew-Eurodrive

Type of application of masses

- High-dense masses, such as the mass of custard, coconut mass, curd mass;

- The mass of dried fruit, etc., with a density of 1500 to 3200 kg / m3;

- Viscosity from 4.0 Pa.c and higher.

Video:

Photo:

Extruder auger unit Intellestamp:

Intellestamp Duo - production of three-component sweets, cheeses, cookies and gingerbread:

Small line - all Intellestamp features in a budget version:

Contact Us, we will be happy to help you!