- Home

-

Production Lines Options

- Candy Production Line

- Gingerbread Production Line

- Cookies Production Line

- Eclairs, Profiteroles, Cupcakes Production Line

- Marshmallow Production Line

- Cookie Sandwiches Production Line

- Halva, Nougat, Iris, Bars Production Line

- Cakes Production Line

- Wafer Sugar Cone with Marshmallows Production Line

- Сurd Snacks Production Line

- Semi-finished Products Production Line

-

Neofood Modules

- IntelleDrop - Multi Lane Food Piston Depositor

- IntelleMix - Molding Machine for Combined Confectionery and Gastronomic Products

- IntelleStamp - Confectionery Auger Extruder

- IntelleGlaze - Enrobing and Decorating Machine

- IntelleWaferBall - Wafer Ball Production Line

- IntelleWaferRoll - Wafer Rolls, Sticks And Bars Production Line

- Intelletartlet - Dispensing Liquid Masses Into Tartlets

- IntelleCone - Waffle Cone Filling Line

- IntelleCake - Fillings Injection Module

- Intellemixer - Mixing And Aerating (Whipping) Machine

- Intelleoven - Confectionery Tunnel Oven

- IntelleCool - Continuous Combined Cooling Tunnel

- IntelleDrive - Central Operations Control Panel

- IntelleRobotics - Robotic Finishing System

- Vending Machines

- Info

- Contact Us

Site last updated: April 12, 2024

A Line Of Equipment for Production of Meat and Fish Semi-finished Products, Meatballs, Nuggets, Salads, Sushi, Pastes, Processed Cheeses

With our equipment you can:

а) To produce many types of products on one production line; quickly rebuild the line from one view to another;

b) To expand the range by increasing the diversity of forms and masses.

c) Almost completely get rid of manual labor, and recoup equipment including on salary savings.

Equipment for the production of semi-finished meat products, including cutlets, nuggets, meat balls, steaks, etc.? No problem!

The complex consists of:

- extruder,

- minced meat supply unit,

- filling unit.

If it is necessary to obtain two-component products, the extruder is equipped with two minced meat supply units.

The type of product is formed using an easily removable set of various nozzles.

The string cutting device mounted on the extruder allows you to get original products of various shapes (for example, nuggets).

The line is completed with a breading unit.

Products are cooled in a refrigeration tunnel or in a freezing spiral complex, with the possibility of adjusting the temperature regime.

Only our equipment allows to produce a calibrated product, equal in weight and shape (due to the use of individual dispensers in the heads of each type), which will allow you to produce a product packaged in boxes, cells and packaging, suitable for promotion in any market and in any trading network!

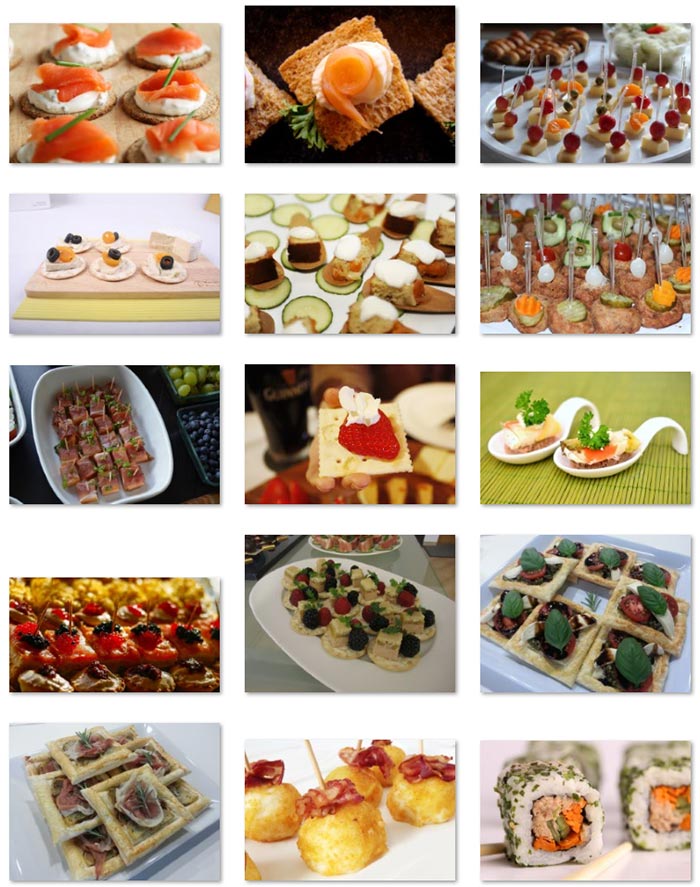

Our equipment can be used for the production of sushi, snacks, salads, pies, processed cheeses!

For example, all this can be produced on one production line:

What kind of equipment do you need?

In this case, the choice of equipment is exclusively an individual approach. We will be based on what types of products you want to produce.

Contact us for equipment advice >>>

РConsider an example of a simple product - cutlets with vegetables.

The basis of the product is minced meat. What to make stuffing, technologist to decide. It can be juicy beef, or a hearty pork, or tender chicken fillet.

Attention! Our equipment lines are formed individually for the client. Any example presented on the site may be:

A) expanded to produce a wider range of products,

B) expanded for greater performance,

C) cheaper for maximum availability, with the possibility of subsequent "upgrade" to the older model.

Contact us for more details!

The base cutlet can be formed with the help of IntelleStamp – a screw module for dosage-molding and daphragm or string cutting. When forming by coextrusion and aperture cutting, we get round balls or oblong sausages with filling. The shape of the products during molding by string cutting can be absolutely any: round, oval, curly, of your choice! It is possible to manufacture products from two masses simultaneously.

Suppose we decide to decorate our cutlet with a vegetable rosette (like marshmallows or a cream rosette on a cake). To do this, we subject the vegetables to heat treatment (frying, stewing, cooking, blanching), then chop in a blender or chopper, mixing with salt, spices, eggs, milk, etc. As a result, we get a bright appetizing vegetable cream: red - from beets or tomatoes, orange - from carrots, green - from sweet pepper, herbs, cucumbers, yellow - from pumpkin, white - from cabbage.

Apply vegetable cream to the meat base using the IntelleMix roller-gear module. The cream is squeezed onto the base through the curly tips that determine the shape of the outlet. The nozzle can make turns at any angle, making the outlet curled like a sink. The combination of several tips makes it possible to apply several colored vegetable fillings at the same time.

Finishing with sauces-liquid ingredients is done using the IntelleDrop piston module.

A servo-system for installing modules and synchronizing their work allows you to alternate the above-mentioned modules, and therefore any layers and combinations of products, in any sequence.

For meatballs, nuggets, cutlets, it is also possible to use mini-lines with a productivity of 150-200 kg / hour:

Video

Contact Us, we will be happy to help you!